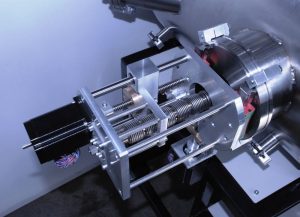

The microproduction activities are carried out within the Prototyping and Microproduction Workshop, which is equipped with high-performance machine tools, such as: 5-axis vertical machining center type DMC 1035Veco with 3D-Siemens numerical control with Shop Mill, CTX 510 ecoline lathe with Siemens numerical control with Shop tower, lathes and modernized milling machines.

The workshop also has a controlled atmosphere welding system especially for stainless steels and aluminum alloys. The workshop employs highly qualified technicians and workers. The level of infrastructure and the quality of the human resources allowed the approach and realization of high technical products having as main beneficiaries CERN Geneva, Leuven Catholic University, Karlruhe Institute of Technology, Chisinau National Institute of Metrology, INCD Materials Physics, Palfinger AG, Ancor Lamina GmBh.