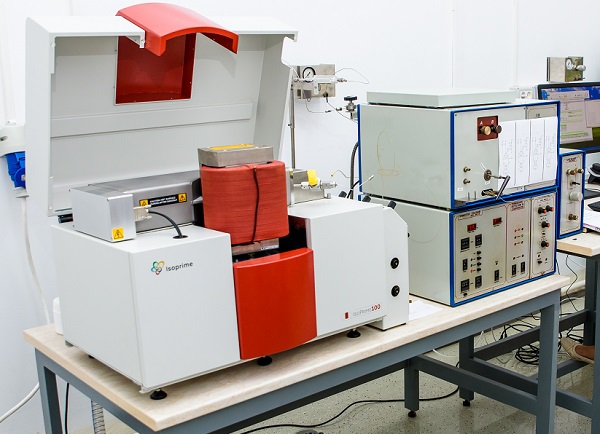

The CCISU is an integrated technological research and innovation infrastructure that incorporates specific technological facilities for isotopic separations, a laboratory for the synthesis of 2H, 13C, 15N, and 18O labeled compounds, and high-tech equipment for isotopic analysis and diagnostics. The organizational structure of CCISU creates a favorable environment for accomplishing the complete value chain, isotopic separation, synthesis of isotopically labeled compounds, and applications of isotopic technologies in areas of high relevance, such as biomedical and advanced materials.

CCISU infrastructure includes:

1. Research and production facilities for stable isotopes

1.1. Isotopic exchange plant for technology research and production of 15N

This is a complex technological research and production plant developed in INCDTIM for the production of 15N by isotopic exchange between nitric acid and nitrogen oxides and is capable of producing nitric acid with an isotopic concentration of over 99% at. 15N.

1.2. Experimental plant for the separation of 13C by cryogenic distillation of carbon monoxide

This is a modular plant consisting of three packed separation columns equipped with an external circuit, which allows experimentation of the separation process under different conditions for the separation of carbon isotopes. The interconnection of the separation columns and the complex monitoring system allows isotope separations to be carried out in a cascade mode or various independent column operating modes and is capable of separating 13C at an isotope concentration of 82%.

1.3. Experimental plant for the separation of 13C by chemical exchange CO2 – carbamate

The separation of carbon isotopes can also be achieved by isotopic exchange between a solution of carbamate and carbon dioxide. The separation plant operating this system has a stainless steel separation column with Helipack packing and is capable of separating 13C at an isotopic concentration of over 8%.