High vacuum chamber for thin film deposition

| The high vacuum chamber was designed and built for thin film deposition by laser ablation, necessary for the growth of nanostructures, as well as for the further development of other applications. Construction: Stainless steel 1.4541 Main components: – Inspection door – Dn400 (1 pc) – Flange section Dn16..40 KF (13 pcs) – Flange section Dn63..200 ISO (13 pcs) – Viewer Dn63…160 (8 pcs) – Adjustable window mount and laser lens (3 pcs) – Adjustable furnace for thin film deposition on silicon (1 pc) – XYZ mobile arm driven by stepper motors (1 pc) – Inner support (made of duralumin, 1 pc) – Adjustable shutter (1 pc) |

|

|

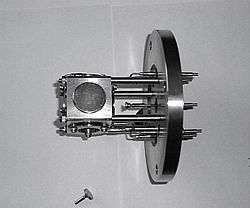

Handling system

| Handling system for the electronic modules of the Hadronic Calorimeter, part of the ATLAS detector at the LHC CERN Geneva – The system is used to extract the electronic “super-drawers” from the calorimeter modules and reinsert them “in situ.”

In recognition of the qualities of the developed system, INCDTIM produced two new handling devices in 2012, incorporating several new solutions due to changes in the ATLAS detector infrastructure. |

|

|

Components for high and preliminary vacuum lines

| KF, ISO, and CF type sections, flanges, and fittings, flanges with vacuum electrical feedthroughs, liquid nitrogen or water traps, etc., intended for the construction of research equipment and industrial applications. Field of application: Types of sections, flanges, and fittings: – DN 10,16,25,40,50 KF – DN 63,100,160,200,250,320,400,500,630 ISO – DN 16,40(35),63,100,160,200,250 CF Construction: Materials: Stainless steel 1.4306 (1.4541, 1.4571), Duraluminum |

|

|

High vacuum chamber

| The high vacuum chamber for thin film deposition was designed and built for the study of quantum interface effects in metal/ C60 nanostructures.

Construction: |

|

|

High vacuum chamber

| The high vacuum chamber was designed and built for the research and development of new materials and technologies and the creation of micro- and nanostructures.

Construction: |

|

|

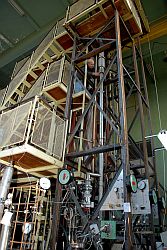

Installation for dynamic processing of substances in a microwave field

| The application refers to a process and installation for dynamic processing of substances in a pulsed microwave field with a wide spectrum of microwave frequencies. This processing mode facilitates, in addition to the thermal effect due to dielectric and magnetic losses, the selective absorption of microwaves at the molecular vibration and translation energy level in the processed substances, thus reducing treatment time, improving processing yields, and expanding chemical processing possibilities.

Features: |

|

|

Robotic system for generating three-dimensional surfaces for laser cleaning techniques

| The aim of the EUREKA project, LARLASC – “Large Area Laser Surface Cleaning” was to develop and implement a new surface cleaning process using unconventional, high-productivity technologies. A mobile surface processing unit was built, capable of cleaning very large surfaces, with a productivity of tens of square meters per hour. At INCDTIM, a tracking system was developed for complex three-dimensional surfaces carrying the working laser module. | |

|

Direct resistive heating furnace

| Features: Coupling flange …………..Dn 63 ISO(CF) Electrical power ……… 1,7 Kw Tmax. ……………………. 2.000 K Cooling water flow… max.16,67 cm3/sec Field of use: The direct resistive heating furnace is designed to operate in a vacuum chamber. It ensures the possibility of obtaining high temperatures without using high voltage power sources. Thanks to the technical solutions adopted in its design and construction, the furnace has high stability and very low thermal inertia and allows for the controlled introduction of gases into the furnace. These characteristics make it suitable for a wide range of applications, among which its use as a source of nanoparticles through adiabatic expansion stands out. Construction: Materials: Stainless steel 1.4306 (1.4541), Ta, ceramic, copper, duralumin, rubber (for sealing) |

|

|

Silicon furnace

| The furnace is designed to operate in a vacuum chamber. It can reach temperatures of 1,100 K. The ceramic furnace support allows the sample to be fixed to the silicon resistance, the furnace to be rotated, and the sample (target) to be moved for centering.

Features: |

|

|

Gold deposition furnace

| The furnace is designed to operate in a vacuum chamber. It allows high temperatures to be reached – 1,300 K – without the use of high-voltage power sources and allows the position of the furnace to be adjusted within the vacuum chamber.

Construction: Coupling flange: Dn63ISO ( Dn 63CF) |

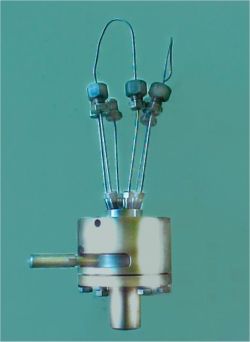

Laser focusing system

| Field of use: The laser focusing system with three degrees of freedom was designed and manufactured to enable the adjustment of the laser beam in vacuum chambers, as close as possible to the target (sample). Construction: Stainless steel 1.4541 Main components: -Coupling flange on Dn63 ISO chamber (1 pc) -Lens adjustment system for different lens-target distances (1 pc) -Window mount -for different window-target distances (1 pc) -Adjustable lens mount (1 pc): -coarse adjustment X-axis: 70mm -fine adjustment X-axis: ±12.5mm -rotation on Y and Z axes: ±100 |

|

|

Wien filter

| The Wien filter is designed to operate in an advanced vacuum chamber and allows the selection of nanoparticles according to their size by applying two fields, electric and magnetic, perpendicular to each other and perpendicular to the axis of movement of the ionized nanoparticles.

Construction: |

|

|

Experimental cryogenic isotope separation facility

Experimental studies for the separation of 13C and 18O isotopes by cryogenic distillation.

| The experimental installation for the separation of 13C by cryogenic distillation of carbon monoxide, designed and built entirely at INCDTIM, allows the mounting of columns with diameters of up to 35 mm. It is served by a liquid nitrogen production plant, the cooling agent used in this process. Carbon monoxide is purified by distillation at a temperature of -193°C, in a specially built plant and is continuously analyzed using a gas chromatograph.

Experimental plant for the separation of 13C by CO2-carbamate chemical exchange The experimental plant for the separation of 13C by CO2-carbamate chemical exchange was designed and built entirely at INCDTIM. Its operation is monitored by sensors measuring the main parameters, and the data is stored on a PC. The chemical exchange separation method is an alternative to cryogenic separation of 13C, but the two can be used in tandem. |

|

|

|

15N separation plant Nitrox system, 99% 15N concentration……

| The technological research and production facility for 15N through isotopic exchange between nitric acid and nitrogen oxides, designed and built entirely at INCDTIM, is capable of producing nitric acid with an isotopic concentration of over 99% at. 15N. The product has enabled the development of highly efficient isotopic technologies for labeling substances with 15N.. | |

|

|

Flow regulator for filtered non-corrosive gases

| Features: Ambient temperature: -10°C … +55°C Pressure range: 1 – 3 bar Flow range: 5 – 10 ml / min Adjustment error: 3% (at a pressure variation of 0.5 bar) Field of use: The regulator is designed for fine adjustment and maintenance of constant flow rates in gas circuits. Construction: Body: brass (CuZn39Pb2) Diaphragm: NBR rubber Seals: Teflon P600 Connection: M8 (other sizes optional) |

|

|

Dn3(4) pressure regulator for filtered gases

| The regulator is designed for fine adjustment and maintenance of constant pressure in gas circuits.

Features: Construction: |

|

|

Dn2 shut-off valve for filtered gases and liquids

| The valve is designed to shut off and open gas or liquid circuits.

Features: Construction: |

|

|

Dn6 control valve for filtered gases

| The valve is designed to regulate the flow in gas and liquid circuits.

Features: Construction: |

|

|

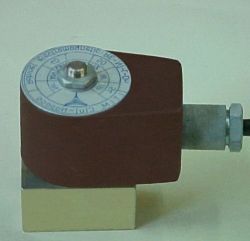

Electromagnetically operated switching valve for gases

| Features: Ambient temperature: -10°C … +55°C Gas temperature: +5°C…+100°C Maximum permissible pressure: 4.5 bar Gas passage sections: 0.5 mm Supply voltage: 48 Vdc Field of application: The valve is designed for switching gas circuits. In chromatography, it is used both as a sample introduction valve and as a switching valve for separation columns. Construction: Body: high-alloy steel: W4112 Drawer: PTFE Connection: M8 (sealed with spherical connection) Connection of channels: -actuated 1-2, 3-4, 5-6, 7-8 -non-actuated 2-3, 4-8, 6-7 |

|

|

Pneumatically operated switching valve for gases

| Features: Ambient temperature: -10°C … +55°C Gas temperature: +5°C…+100°C Maximum permissible pressure: 4.5 bar Gas passage cross-section: 0.5 mm Compressed air pressure: 4 bar Application: The valve is designed for switching gas circuits. In chromatography, it is used both as a sample introduction valve and as a switching valve for separation columns. Construction: Body: high-alloy steel: W4112 Spool: PTFE Connection: M8 (sealed with ball joint) Connection of channels: -actuated 1-2, 3-4, 5-6, 7-8 -non-actuated 2-3, 4-8, 6-7 |

|

|

Electromagnetic switching valve type RC1E or electric motor type RC2E for filtered gases

| The valve is designed for switching pneumatic circuits in automated equipment.

Features: Construction: |

|

|

SI100 type sample introduction valve for liquids

| Features: Ambient temperature: +5°C … +55°C Liquid temperature: +20°C…+80°C Maximum permissible pressure: 450 bar Sample loss during injection: 2-5 volumes equivalent to the sample loop volume Sample loop volume range: 5.ul – 2.5ml Liquid passage sections:.. 0.5 mm Actuation torque: max…….. 15daNcm Drawer rotation angle:…. 60° Field of use: The valve is designed to switch high-pressure liquid circuits, with 6 ports with external sample loop. Construction: Materials in contact with the sample: stainless steel W4571, PTFE, ceramic Connection: M8 (sealed with connection) |

SI200 sample introduction valve for liquids

| Features: Ambient temperature: +5°C … +55°C Liquid temperature:…………… +20°C…+80°C Maximum permissible pressure:. 450 bar Sample loss during injection:……. 0 Sample loop volume range: 5.0 – 5ml Liquid passage sections: 0.5 mm Actuation torque: max…… 15daNcm Drawer rotation angle:.. 60° Injection syringe: Lauer type (d=0.7mm, l=55mm) Field of use: The valve is designed to switch high-pressure fluid circuits and has 6 ports with an internal injection port. Construction: Materials in contact with the sample: W4571 stainless steel, Teflon P600, ceramic Connection: M8 (sealed with spherical connection) |

|

|

Control valve -RR1 for filtered gases

| Features: Ambient temperature: -10°C … +55°C Fluid temperature: +5°C…+80°C Maximum permissible pressure: 5 bar Maximum flow rate: 100 ml/min Application: The valve is designed for fine adjustment of gas flow in circuits used for analysis processes. Construction: Body: stainless steel W4571 or brass CuZn39Pb2 Seals: Teflon P600 Connection: M8 (other sizes optional) |

|

|

High vacuum valve for gases

| Features: Min. gas flow rate: 10-8 mbar l/s Max. gas flow rate for Pi=1 bar: 600 mbar l/s Max. degassing temperature: – 4500C for valve with CF flanges – 800C for valve with KF flanges Maximum permissible pressure: 1 bar Application: The valve is designed for the controlled introduction of gases into high vacuum systems. Fine adjustment is achieved by turning the micrometric screw. Construction: Body: stainless steel: W4571 Drawer: ceramic (Duralumin) Separation membrane: 1.4571 Connection: -on the high vacuum line Dn35CF(40KF) -on the introduction line Dn16CF(16KF) |

|

|

Tap introduced for filtered gas samples

| Features: Ambient temperature: -10°C … +55°C Gas temperature: +5°C…+100°C Maximum permissible pressure: 6 bar Gas passage sections: 2 mm Drawer rotation angle: 60° Number of ports: 6 Area of application: The valve is designed for switching gas circuits. In chromatography, it is also used for introducing the sample volume. Construction: Materials in contact with the sample: stainless steel 1.4571 or brass, PTFE Connection: M8 (sealed with ball joint) |

|

|

Dn2 fine adjustment valve for gases and liquids

| The valve is designed for fine adjustment of the flow rate in gas and liquid circuits. Features: Ambient temperature: -10°C … +55°C Fluid temperature: +5°C…+80°C Maximum permissible pressure: 200 bar Maximum flow rate: 15 l / min Field of application: The valve is designed for flow control in gas and liquid circuits. Construction: Body: stainless steel 1.4571 or brass Stem: high-alloy steel 90Cr180 Seat: PTFE Connection: M14x1.5 (and sealing with stainless steel or brass ball connection) |

|

|

Restrictor valve for filtered gases

| Features: Ambient temperature: -10°C … +55°C Fluid temperature: +5°C …+80°C Maximum permissible pressure: 4.5 bar Maximum flow rate: 150 ml / min Field of application: The valve is designed for fine adjustment of the gas flow in circuits intended for analysis processes. Construction: Body: stainless steel 1.4571 or brass Seat: PTFE Seals: PF60A rubber Connection: M14x1.5 (sealed with spherical connection) |

|

|

RSC100 type circuit selection valve for gases and liquids

| Features: Ambient temperature: +5°C … +55°C Liquid temperature: +20°C…+80°C Maximum permissible pressure: 25 bar Flow range: 10… 200ml Number of selectable flows: 8 Supply voltage: 220V Application: The valve is driven by a stepper motor and is designed to select gas or liquid flows. Flow selection is programmed on a computer. Construction: Materials in contact with the sample: stainless steel 1.4571, PTFE. Connection: M8 (sealed with spherical connection) |

|

|

DN6 electropneumatic distributor for filtered, lubricated air or neutral gas, 5-way/2-position

| The 5-way/2-position electropneumatic distributor for filtered, lubricated air or neutral gas is used in automated pneumatic lines. Features: Ambient temperature: -10°C … +55°C Fluid temperature: 0°C…+80°C Maximum permissible pressure: 6 bar Minimum number of connections: 400,000 Maximum connection frequency: 30/min Field of application: The 5-way, 2-position electro-pneumatic distributor for filtered, lubricated air or neutral gas is used in automated pneumatic lines. Construction: Body: duralumin (or brass) Sealing gaskets: NBR rubber, P600 Teflon Protection rating: IP54 Climate protection: THA3 Connection: G1/4 (other sizes optional) |

|

|

Electromagnetic valve Dn1.5…4 for filtered non-corrosive gases and liquids 2-way/2-position or 3-way/2-position

| The 2-way/2-position electromagnetic valve is designed for the automation of pneumatic and/or hydraulic circuits in scientific equipment and industrial applications. Features: Ambient temperature: -10°C … +55°C Fluid temperature:…………………..0°C…+80°C Maximum permissible pressure:…….40 bar Maximum permissible viscosity:… 40 centistokes Minimum number of connections:………400000 Maximum connection frequency:. 40/min Field of use: The 2-way/2-position or 3-way/2-position indirect-acting solenoid valve is designed for the automation of pneumatic and/or hydraulic circuits in scientific equipment and industrial applications. Construction: Body: brass (or stainless steel) Sealing gaskets: NBR rubber Degree of protection: IP54 Climate protection: THA3 Connection: G1/4 (other sizes optional) Power supply signaling: SD (optional) Power cable: l=0.5m (standard) |

|

|

Dn14 electromagnetic valve for filtered non-corrosive gases and liquids 2-way/2-position

| Features: Ambient temperature: -10°C … +55°C Fluid temperature:…………………. 0°C…+80°C Maximum permissible pressure:…. 20 bar Pressure difference:……………… 0.1 to 15 bar Maximum permissible viscosity: 40 centistokes Minimum number of connections:…… .400,000 Maximum connection frequency: 40/minExample of electromagnetic valve notation: VE2/2 – Dn14/ G1/2 / 24Vdc / SD / l=1.5m Field of application: The 2-way, 2-position, indirectly operated solenoid valve is designed for the automation of pneumatic and/or hydraulic circuits in scientific equipment and for industrial applications. Construction: Body: duralumin Sealing gaskets: NBR rubber Protection rating: IP54 Climate protection: THA3 Connection: G1/2 (other sizes optional) Power supply signal: SD (optional) Power cable: l=0.5m (standard) |

|

|

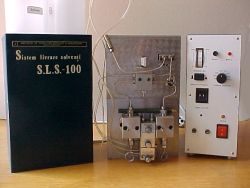

SLS100 solvent delivery system for liquid chromatography

| Features: Ambient temperature: +10°C … +40°C Pump flow rate: 100 ml/stroke Delivery flow range: 0.1…10 ml/min Flow programming: incremental increase of 0.1 ml/min Working pressure range: 0…400 bar Pressure stability: <2.5% amplitude for pressure >10 bar Supply voltage: 220V Range of use: The SLS100 solvent delivery system is designed for high-performance liquid chromatographs (HPLC), supplying the HPLC system with solvent under strict pressure and flow conditions. The SLS100 can be used as a stand-alone unit in various applications requiring fine liquid dosing. The SLS100 consists of a hydraulic module (which mainly has a constant flow suction-repulsion pump with two pistons offset by 180°, a flow pulsation damping unit) and an electronic module. Construction: Materials in contact with the sample: stainless steel 1.4571, PTFE, kel-F, sapphire, ruby. |

|

|

XZ manipulator

| The XZ mobile arm, driven by stepper motors, was designed for positioning the sample (target) in vacuum chambers. Features: Coupling flange: Dn160-ISO x = +15mm z = +35mm |